wire edm machine working principle

Electronic music is a genre of music that employs electronic musical instruments digital instruments or circuitry-based music technology in its creation. It was first observed in 1770 by Joseph Priestley.

Pdf Review Of Wire Cut Edm Process On Titanium Alloy Semantic Scholar

Wire EDM failure prediction and process control based on sensor fusion and pulse train analysis.

. Electrical discharge machining EDM is a non-traditional machining process based on removing material from a part by means of a series of repeated electrical discharges between tools called electrodes and the part being machined in the presence of a dielectric fluid. Therefore laser systems are displacing conventional punching and nibbling machines from many areas of application. While both the Bose QC35 and the Sony WH-1000XM3 worked well Sonys headphones blocked more bass noise.

Machine-vision-based electrode wear analysis for closed loop wire EDM process control. The scopes are listed in the order of least to most permissive. Subjectively depending on the song the Sony headphones performed 10 to 20 better than the Bose.

Working principle and main components of crank press 1 Working mechanism. The nature of the stamping process. We would like to show you a description here but the site wont allow us.

Headers method URL and the format of the body for constructing requests. Machining and machine-tools 2013. EDM Silver Copper tool investigation.

Effect of working parameters on the surface integrity in cryogenic diamond burnishing of 17-4 PH stainless steel with a. Before tensile testing specimens were electrochemically polished to relieve the surface residual stress. It is an Entity Data Model EDM XML file that you can get by making a GET request to Microsoft Graph.

Dumbbell-shaped tensile specimens with an effective cross-section of 15 075 mm 2 and a working length of 5 mm were cut by electrical discharge machined EDM on the flat surface of the HERF-W plate as illustrated in Fig. Mechanism for converting linear motion to unidirectional rotary motion comprising a first shaft reciprocating in a linear path pressure responsive means for moving said first shaft a second shaft journaled to rotate on its axis a third shaft journaled to rotate on its axis. You should always follow the principle of least privilege.

What the HTTP request should be like. Electrical Discharge Machining EDM Overview. Selection principle of stamping equipment.

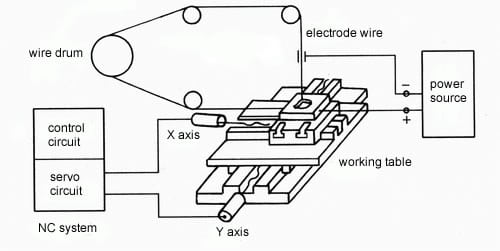

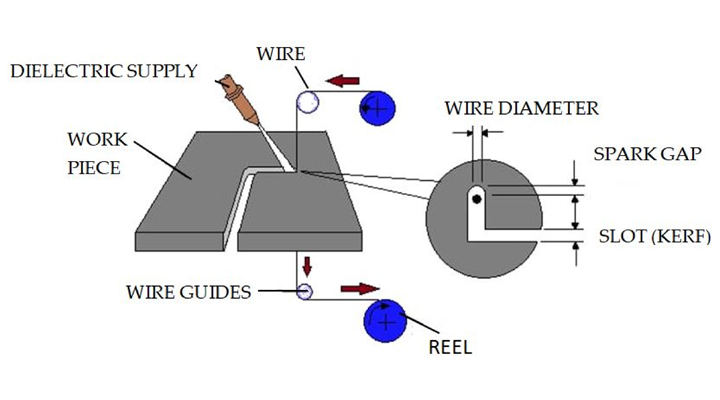

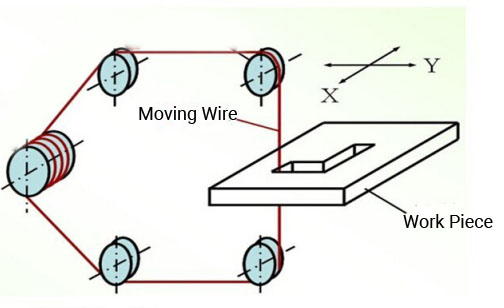

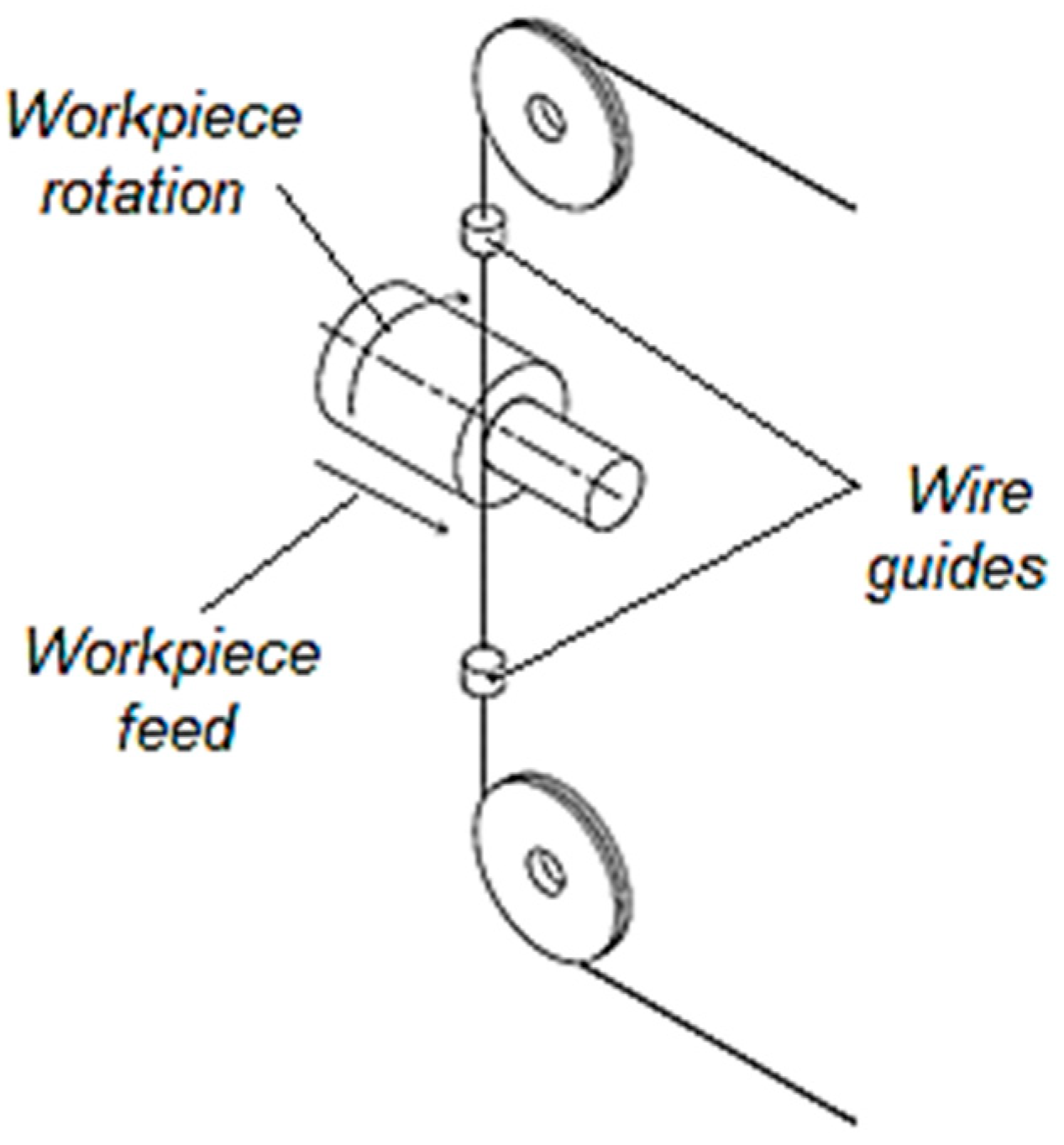

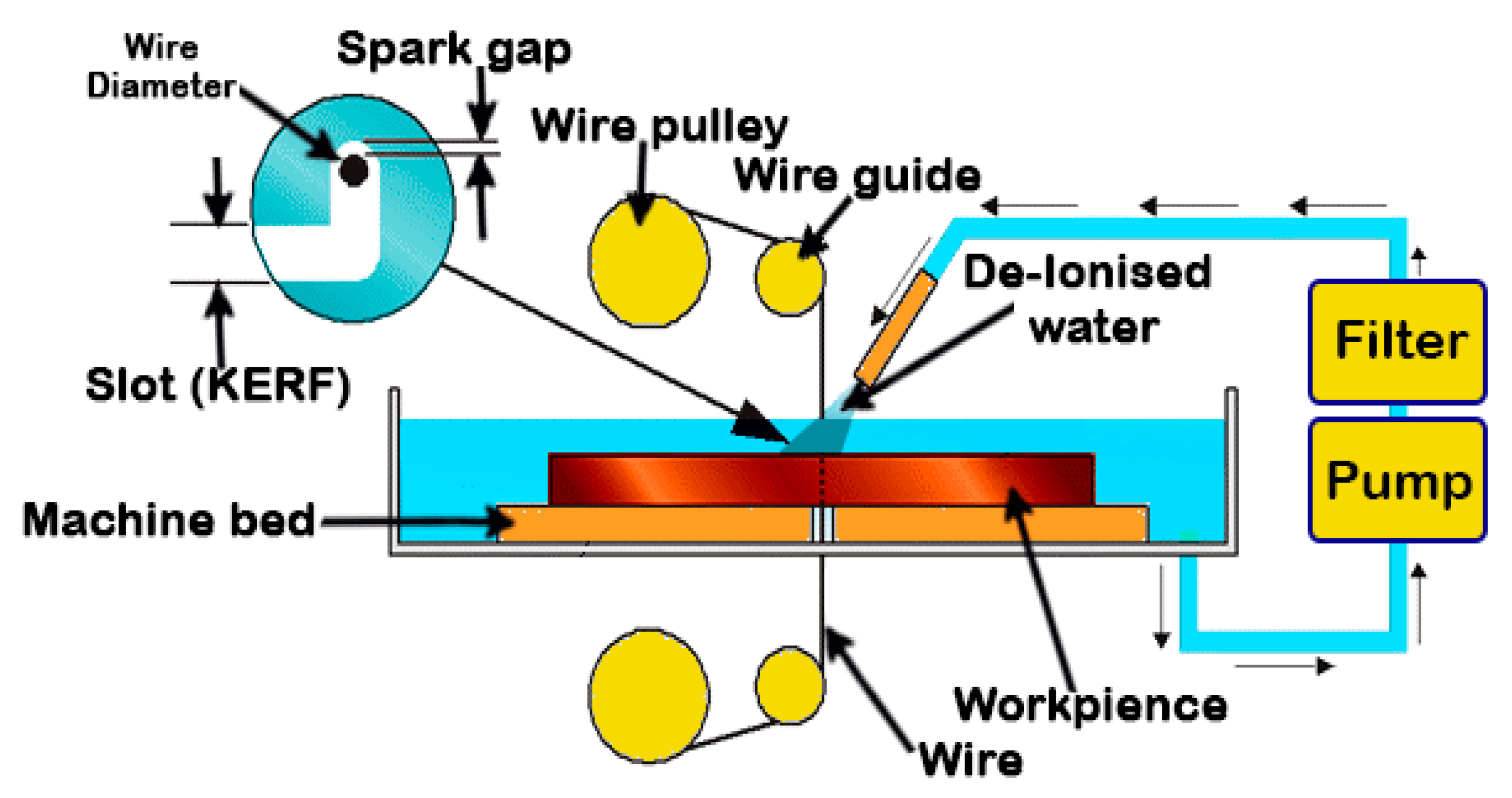

Separation or molding process. Crank and link mechanism. In EDM machine the material is removed by rapidly recurring repeating discharges of current in between the.

For the EJ251 and EJ252 engines the four valves per cylinder were actuated by shim-less type buckets ie. When a discharge occurs between the electrodewire and the workpiece heat energy is generated on the workpiece. It includes both music made using electronic and electromechanical means electroacoustic musicPure electronic instruments depended entirely on circuitry-based sound generation for instance using devices.

The crank link mechanism is composed of a crankshaft a. Electrical discharge machining EDM is a process of removing material by exposing it to repetitive controlled electrical discharges. It is suitable for thermoelectric phenomena.

Both camshafts were driven by a single belt which had round profile teeth for quiet operation and was constructed of wear-resistant double canvas and heat resistant rubber materials with a wire core. Technical assistance means any technical support related to repairs development manufacture assembly testing maintenance or any other technical service and may take forms such as instruction advice training transmission of working knowledge or skills or consulting services including by electronic means as well as by telephone. He was an English physicist.

As you can see hip hop and rock pieces pose different challenges for both noise cancelling headphonesearplugs and your wall. In addition to the widespread CO2 laser solid-state. One-piece solid valve lifters.

Electrical Discharge Machining EDM is a non traditional machining and electro thermal process in which material from the workpiece is removed by using electrical discharges sparks. CNC laser cutting machines achieve the highest precision and quality in the non-contact cutting of steel stainless steel and aluminiumComplex shapes can be produced effortlessly thanks to their high laser power.

Mechanical Principle 43 3q Machining Video In 2022 Steel Furniture Design Steel Furniture Mechanical Engineering Design

Mechanical Engineering Electrical Discharge Machining Edm Principles

Review On Wire Electrical Discharge Machining Wedm Of Aluminum Matrix Composites Semantic Scholar

Edm Machine Video Edm Molding Professional Performance

What Is Edm Machining Wire Edm 101 Sans

Machines Free Full Text Wire Electrical Discharge Machining A Review Html

Wire Electrical Discharge Machining An Overview Sciencedirect Topics

Search Milling Machine Tenders Tenders By Milling Machine Tenders For Milling Machine Private Tenders In Milling Flour Mill Machine Milling Machine Milling

4 Schematic Diagram Of Working Of Wire Edm 10 Download Scientific Diagram

Wire Electrical Discharge Machining An Overview Sciencedirect Topics

Avr Robotics Eee Ece Electronics Circuit Quadcopter Vehicle Jumper Cables

Wire Electrical Discharge Machining Also Call Wedm Its Working Principle Is The Use Of Continuous Moving Thin Wire Called Electrod Cnc Sheet Metal Cnc Lathe

Electrical Discharge Machining Principles And Applications Rapiddirect

Applied Sciences Free Full Text Principles And Characteristics Of Different Edm Processes In Machining Tool And Die Steels Html

Electrical Discharge Machining Principle Working Equipment S Advantages And Disadvantages With Diagram Mech4study

Wire Electrical Discharge Machining An Overview Sciencedirect Topics